In this post, we will be discussing Top Loader gantry robots — specifically models from FANUC. These robots differ significantly from standard gantry robots, and here’s why:

FANUC Top Loader Series Robots

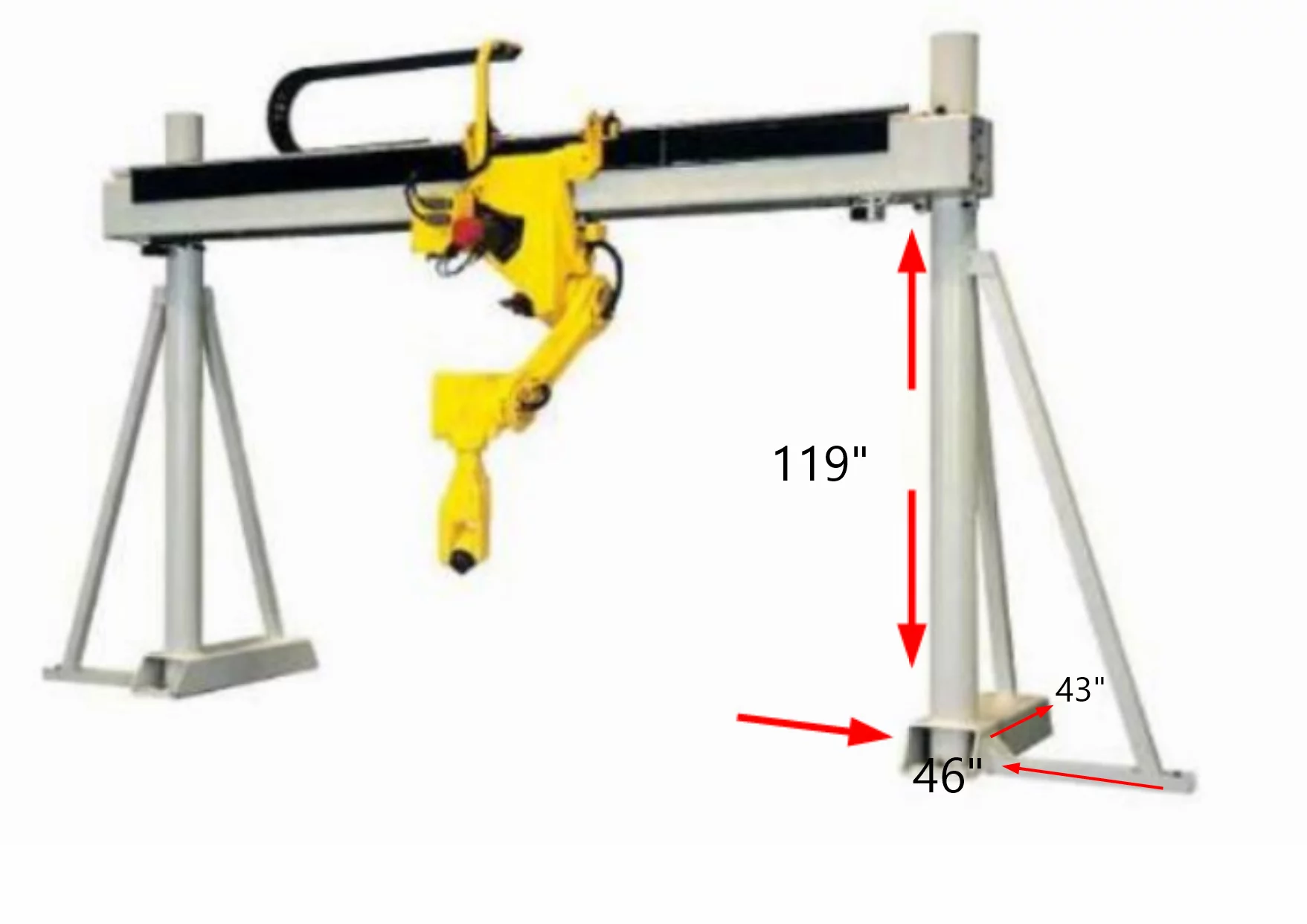

In Top Loader gantry robots, overhead rail-mounted robots with six joints and modular architecture provide FANUC loaders with maximum range and servo-electric operation.

The Top Loader series fits a variety of industries and applications, offering multiple rail lengths, payloads from 20 to 200 kg, and a reach of 1.6 to 2.2 meters.

Universal Robotic Inc. offers the strongest line of Top Loader robots in this category.

Combining multiple advantages, the Top Loader Series is an ideal solution for machine-tool loading/unloading and extraction from molding machines.

Compared to traditional linear portal robots, FANUC Top Loaders reduce floor space and height requirements.

Their versatility allows them to perform value-added post-processing tasks, including trimming, deflashing, marking, inspection, packaging, and palletizing.

When installed, FANUC gantry robots help maximize machine access and improve layout efficiency.

Mounting these robots on a rail lets them service multiple vertical and horizontal machines with various configuration options.

Here are key advantages of having a Top Loader Gantry Robot

1. Flexible cell design

For added flexibility, two Top Loader robots can be mounted within a cell.

They can also perform post-processing tasks as part of the automation system.

2. Top speed & motion performance

FANUC Top Loader robots deliver exceptional performance thanks to high-speed axes, precise patented reducers, and durable motors.

This results in excellent reliability and repeatability.

3. Service multiple machines

Mounting a FANUC Top Loader robot on a rail enables it to service several vertical and/or horizontal machines, reducing overall investment costs.

Top Loader Gantry Robot Models Available at Universal Robotic INC