The Selective Compliance Assembly Robot Arm robots, or SCARA robots, are a key technology in contemporary world automation. SCARA robots are famous due to their special construction and functions, which are popular in many industries, such as those that are precise and require speed are industries. Readers will get to know about the SCARA robot in this article: SCARA robot’s definition, types, variations, pros and cons, uses in various industries, and their comparison with other types of robots.

What is a SCARA Robot?

A SCARA robot is a kind of industrial robot that is typified by the unusual arm structure that enables it to do so to be obeyed selectively in the horizontal direction and to be rigid in the vertical direction. This design allows SCARA robots to undertake assignments like assembly, pick and place, and so on fast and precise packaging. Generally, SCARA robots include four motion axes: two of them horizontal motion, one vertical, and one rotational motion.

The pioneer SCARA robot was launched in the late 1970s, and since that time, they have become popular because of the following reasons for their effectiveness in high-speed applications. The SCARA robots will have an ability to reach up to 1 meter per second and repeatability of +-0.01 m, thus ideal in activities that demand accuracy. SCARA robots are diverse and can be configured with a payload of grams to several kilograms, modified in different ways to suit different industries.

Types and Variations

SCARA robots are available in different types and configurations, thus they can be specialized for particular tasks and industries. It is important to know these differences in order to be able to choose the appropriate robot application.

By Axis Configuration

SCARA robots are mainly distinguished by the axis pattern. The most widespread set up has four axes, which give it a combination of rotational and linear movements. Some advanced models can be provided with more axes to be more flexible and allow more complicated tasks. For example, the standard SCARA four-axis robot could have a reach of 1,000 mm and a payload capacity of around 10 kg. This structure works best in those tasks that mandate a horizontal assembly, e.g., assembly lines and wrapping.

Application Specialization by Application Specialization.

Another classification of SCARA robots is according to the area of application. Some robots are designed whereas other tasks may be optimized for precision tasks, high-speed assembly tasks can be performed soldering or inspection. As an example, SCARA robots used in electronic production typically have end-effectors that are specialized to deal with delicate parts, whereas those in the automotive industry can be rigged to carry greater weight. SCARA robots can be used to perform well in this specialization in their respective disciplines, and increasing their productivity and efficiency.

Advantages and Disadvantages

Even though SCARA robots have many advantages, they present some limitations as well. Understanding the two parties is critical in making sound decisions on how they will implement the same.

Advantages

Speed

The speed of SCARA robots is one of the most important benefits. These robots are able to work under high-speed velocities that are usually greater than 1 meter per second. This velocity is especially useful in high-volume production settings, where efficiency is the key factor. SCARA robots can cycle due to their rapid times, resulting in improved throughput and lower costs of operation.

Cost-Effectiveness

SCARA robots are not very expensive compared to other robotic solutions, especially in cases of work where it is needed to scratch need to be fast and accuracy are needed. Their less complicated design and fewer elements make them lower cost of manufacturing and maintenance. Also, the possibility of automating efforts can result in macroeconomic savings in labor, and SCARA robots are worth consideration by enterprises that aim to optimize their operations.

Ease of Programming

SCARA robots are fairly easy to program due to user-friendly interfaces and software. Lots of SCARA robots are provided with user-friendly programming software that enables the operator to program and configure robots’ tasks quickly. This simplicity in programming saves time and allows businesses to fit the varying needs production requires within an economy.

Accuracy and Consistency

SCARA robots have high precision and repeatability with values typically of +-0.01 mm. Such a degree of precision is essential to the applications that demand the same conclusions, like assembly and inspection tasks. Loose tolerances improve product quality and waste minimization.

Cleanroom Compatibility

Most of the SCARA robots are configured to work in clean room settings and hence they are applicable in industries such as pharmaceuticals, electronics. Such robots may be made using materials that minimize contamination, and most of them have features that inhibit the dust build-up and particles, so as to guarantee strict adherence to high standards of cleanliness.

Disadvantages

Limited Flexibility

Among the main drawbacks of SCARA robots, one can note a relatively high lack of flexibility in comparison to other robot types. They are excellent at certain activities, but their design does not able to allow them to do complicated activities, motions, or a great variety of activities. This is the limitation that may be a disadvantage in the surroundings that require versatility.

Payload Constraints

SCARA robots come with certain payloads, and this feature can be a constraint in some cases. While some of them have moderate loads, they might not be applicable to those that are heavier components. Companies need to be extremely careful about the needs so that the selected SCARA robot can meet them and adjust the necessary payload.

Applications and Industry Usage Cases

SCARA robots are used in different industries, and each industry is enjoying the advantages of their abilities. Knowledge of these applications would enable businesses to determine areas where they can automate.

Electronics Manufacturing

SCARA robots are also common in electronics manufacturing, where they are used in assembly, soldering, and testing components. They are fast and accurate, and necessary to work with vulnerable components, like circuit boards and microchips. SCARA robots are capable of running at high speeds, and hence they can do a lot to increase production rates and decrease time-to-market on electronic products.

Consumer Electronics and Small Appliances

The SCARA robots are important in the manufacture of consumer electronics and small appliances. They are frequently used in assembly lines, e.g., in place components and packaging. The robots & capability of working with lightweight elements with high accuracy make sure that products are of quality standards and at the same time maintain efficient production processes.

Automotive Industry

SCARA robots find applications in the automotive industry; some of them are assembly, welding, etc., and material handling. They can withstand heavier parts due to their sturdy design, which enables them to support heavier parts, and a suitable assembly of engines and chassis. SCARA has a rapid and precise speed; robots help in the streamlining of production lines and enhance efficiency in general.

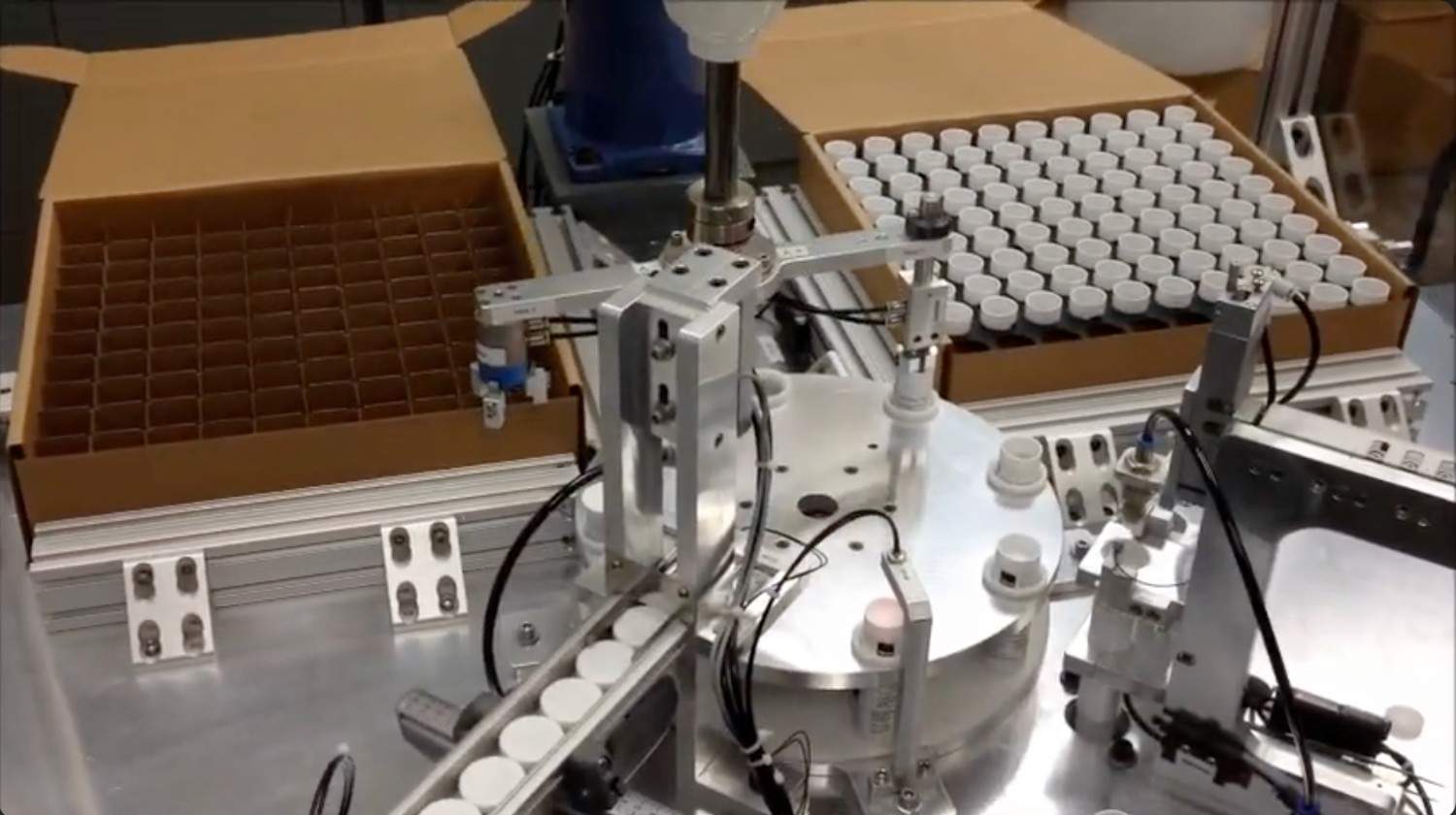

Pharmaceutical and Medical Devices manufacturing

In the pharmaceutical and medical device industries, SCARA robots are becoming more popular because of their cleanroom capability and accuracy. They are used to do activities like filling, packaging, and so on medical product inspection. This is necessary because of the high cleanliness and accuracy levels in such industries where the quality and safety of products are of the greatest importance.

Processing of Food and Beverages

SCARA robots have their application in the food and beverage industry in the packaging, sorting, and assembly. The speed and efficiency are used to simplify the production processes and ensure that products are packed quickly and accurately. Further on, SCARA robots may be fitted to comply with food safety standards, rendering them appropriate to work with consumable goods.

Comparisons with Other Types of Robots

The SCARA robots should be compared to other types of robots when it comes to automation solutions robots to identify the most suitable ones to use.

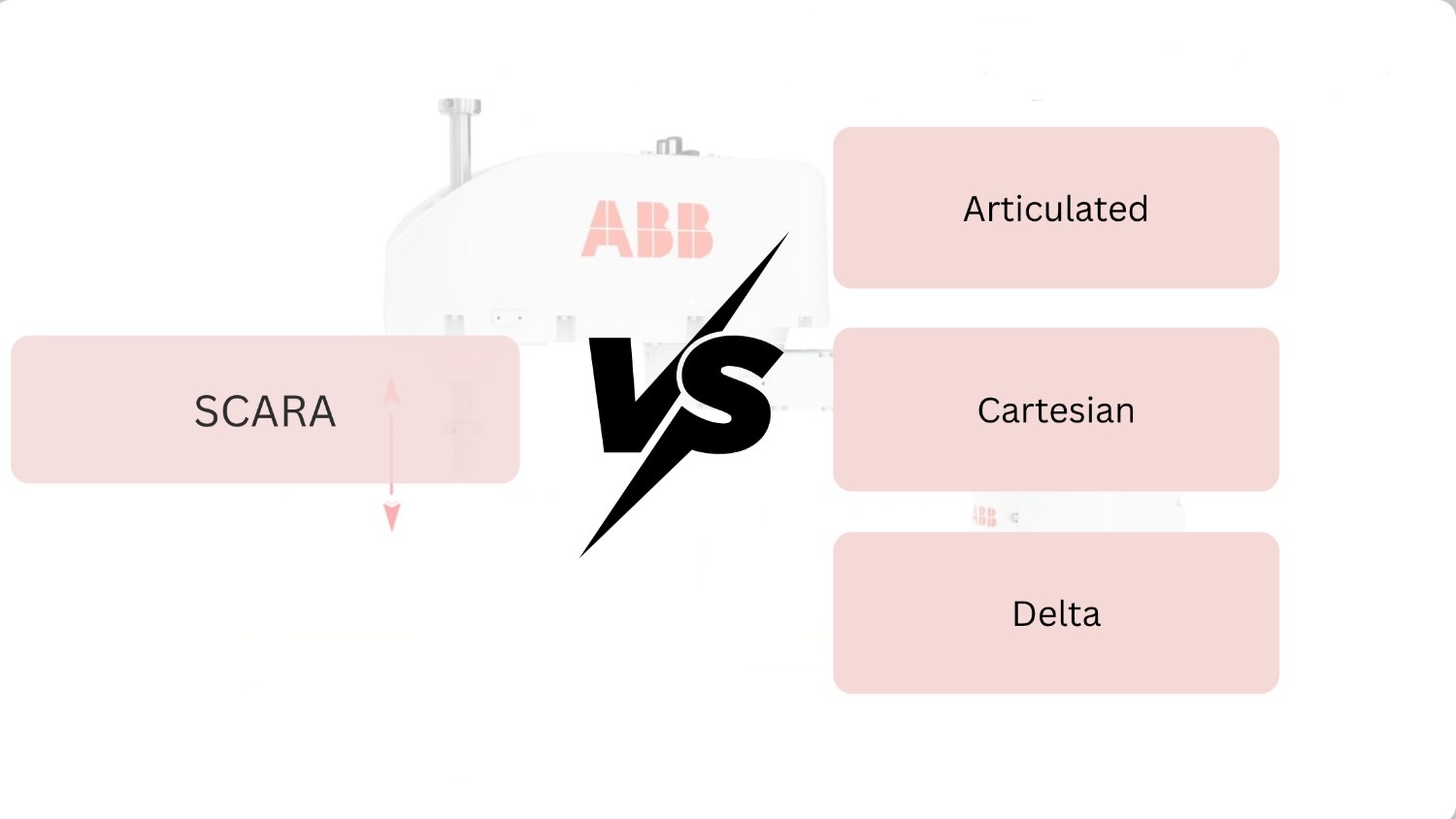

SCARA vs. Articulated

SCARA robots are different in design and robots compared to articulated robots. While SCARA robots excel in articulated robots are more flexible and capable of movement range, horizontal motions, and speed are also possible. Articulated robots will be more useful in complex tasks that need multi-directional movement.

SCARA robots are suitable for high-speed and repetitive duties.

SCARA vs. Cartesian Robots

In comparison to Cartesian robots, SCARA robots are smaller in design and quicker. Cartesian robots move on three linear planes and are commonly applicable to jobs that demand high precision of linear movements. The SCARA robots, however, have higher speeds and are more efficient in assembly and pick-and-place applications.

SCARA vs. Delta Robots

Delta robots are characterized by high-speed virtues, and they are commonly applied in packaging and sorting applications. Although both SCARA and delta robots are effective in speed, delta robots normally have a higher one moved range and is able to work on more complicated tasks. SCARA robots, in turn, are more appropriate where strict up and down movement and accuracy of position are needed.

Conclusion

To conclude, SCARA robots are an essential part of modern automation, providing speed, accuracy, and cost-efficiency in different industries. They are designed in such a way that they are easily handled to perform tasks within their electronics production, car assembly, and so on. Although they are limited in terms of flexibility, their benefits, payload capacity are a good choice to consider when improvements are required for business productivity. It may be helpful to learn about the various kinds of SCARA robots and their use. With the help of information, organizations are able to make the right decisions regarding the formulation of automation in their operations.