The welding robots have transformed the manufacturing industry through enhanced accuracy, efficiency, and safety in the welding process. These robotic systems perform various welding tasks, which are highly uniform, which rules out the element of human error, and which improves productivity.

What Are Welding Robots?

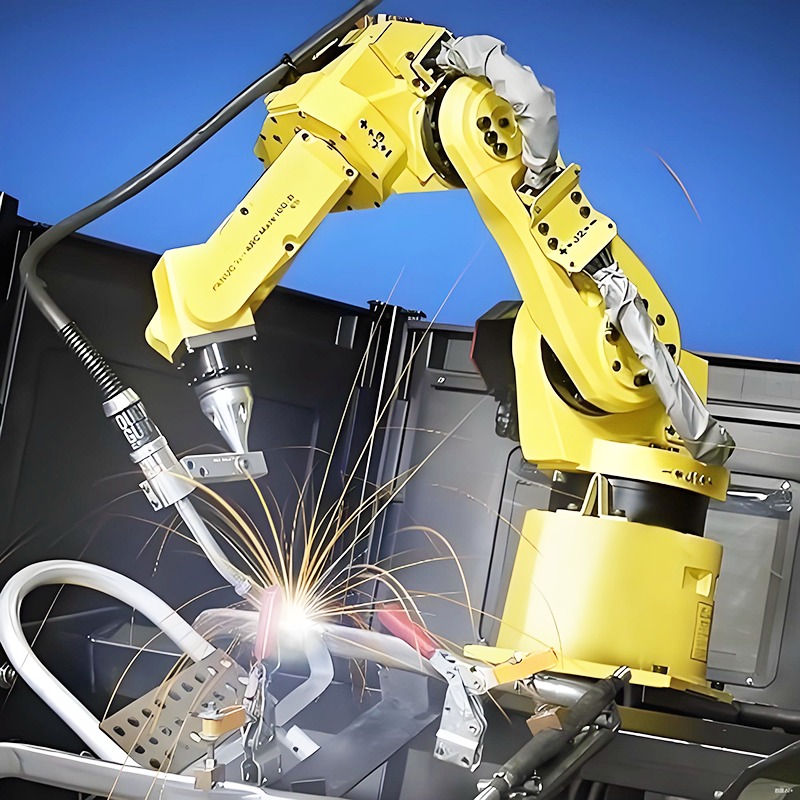

The robots used to perform the welding exercise are computerized machines, which are very precise and consistent in performing the exercise. These are equipped with sophisticated sensors and computerized control systems and are utilized to make various kinds of welding, including arc welding, spot welding, and laser welding. Moreover, it has been anticipated that the global market of welding robots will cost approximately 4.5 billion dollars in 2024, with the rate approaching 7.2 billion dollars in 2032, with a compound annual growth rate (CAGR) of 6.1.

Advantages

- Greater Accuracy: Welding robots offer the quality and accuracy of human-reduced error in welding.

- Increased Productivity: They also operate twenty-four hours, thus increasing productivity.

- Safety is improved: The risk of being exposed to dangerous conditions is not experienced by human beings since the work is done by robots.

- Cost Savings: Automation will save the workforce and reduce wastage.

- Flexibility: Re-programming robots will offer them flexibility in other welding activities.

Disadvantages

- High Start-up Cost: The Initial cost of purchasing and installing welding robots can be colossal.

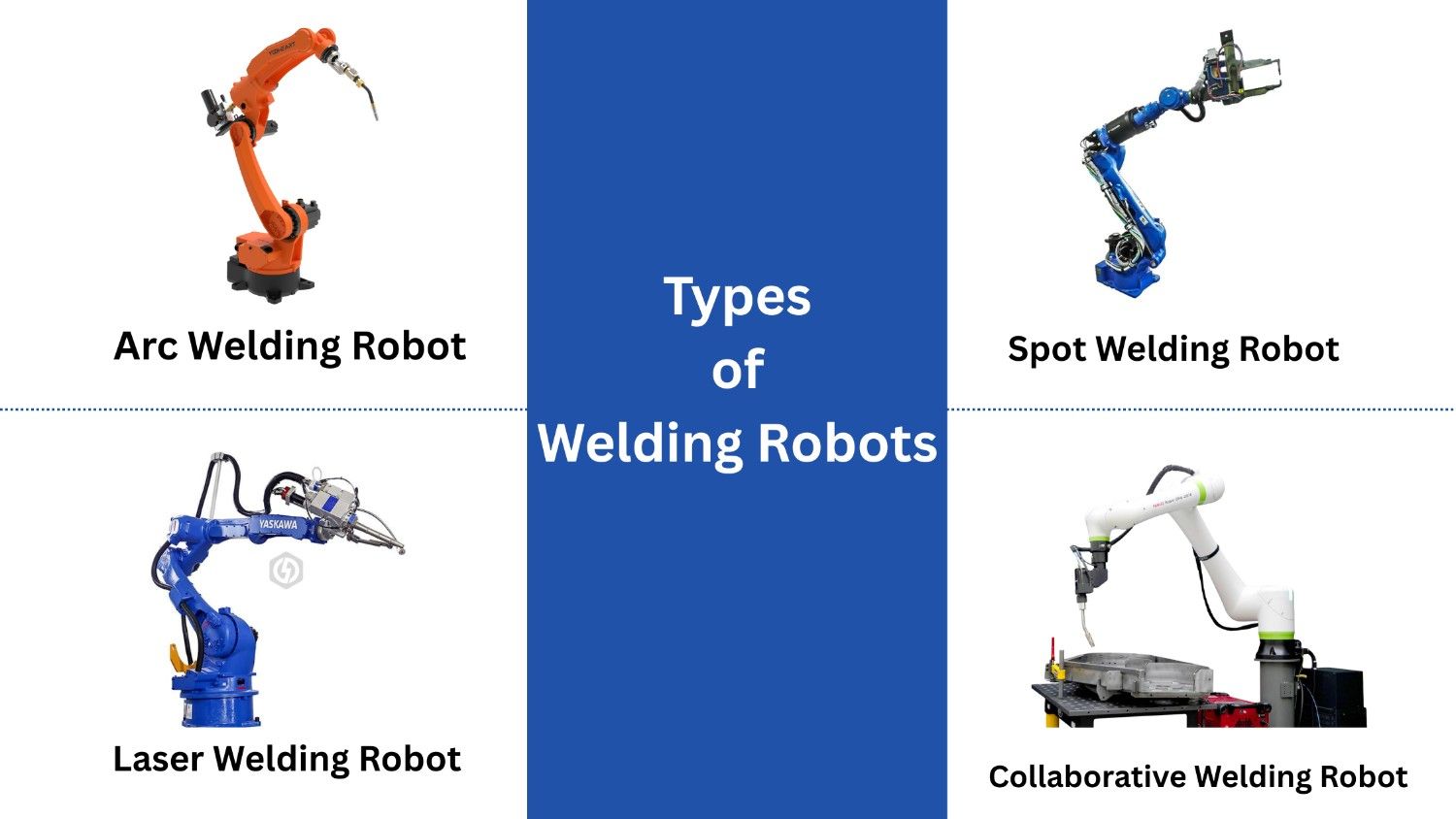

Types of Welding Robots

The type of welding is another category of welding robots. Here are the 4 major types of welding robots:

Arc Welding Robot

The Arc welding robots will be used in such spheres of activity as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. They are widely applied to the building of ships and the heavy equipment field, and the construction of the infrastructure as well. The smoothness of six-axis robots in trajectory control and adaptive motion planning allows them to remain on a uniform arc and achieve welding penetration at difficult angles.

Spot Welding Robot

They are applied in the automotive sector primarily, where the Spot welding robots find use in welding metal sheets. Their cycle time is extremely low, and they are very efficient; thus, they are extremely appropriate for mass production. The six-axis welding robots within the spot welding robots subcategory had an equivalent distance of 42 in market share in 2024.

Laser Welding Robot

Laser welding robots are designed to use focused laser beams to bond materials, and this is very precise, so that very little distortion of heat is created. They are also venturing into other sectors such as aerospace and electronics.

Collaborative Welding Robot

The welding robot also possesses cobots that will liaise with the human workers. They best suit small and medium-sized businesses to be utilized as long as they are flexible and can be easily coded. The collaborative robots are also in high demand, and companies such as KUKA and ABB are leading in this sphere.

Applications and Industry Standards

They have both been used in industrial applications and standards. The welding robot identifies with industries, thus facilitating productivity and giving a high level of welds.

Automotive

It will need the welding robot, like chassis building and body-in-white, in the automotive industry. In 2024, the automotive industry had more than forty-five percent of the total amount of all the welding robots in the world.

Heavy Equipment

The welding robots find their application in the manufacturing of heavy equipment because they are engaged in structural welding and assemblies. They are rather stringent and efficient in terms of the production of massive machinery.

Pressure Vessels

The manufacture of the pressure vessels also uses a welding robot to accomplish the welds, which are uniform and of quality, which is important in the safety and performance.

Shipbuilding

Through the welding of robot, hull and bulkhead welding is performed in the shipbuilding process. This type of robot can access closed spaces of ships much more easily, besides cutting down on the level of welding by almost 30 percent.

Aerospace

Welding robots are used in the aerospace industry to perform fuselage and engine parts assembly. The accuracy demanded by such robots is such that it can help achieve high-quality standards in the industry.

Comparison of Manual Welding and Robot Welding

A comparison of robotic and manual welding reveals a number of significant distinctions:

| Aspect | Manual Welding | Robotic Welding |

| Precision | Dependent on the welder’s skill | High consistency and accuracy |

| Speed | Slower due to human limitations | Faster with continuous operation |

| Safety | Exposure to hazardous fumes and heat | Reduced human exposure to dangerous conditions |

| Cost | Lower initial investment | Higher upfront cost, but cost-effective in the long run |

| Flexibility | Limited to the welder’s capabilities | Easily reprogrammable for a variety of tasks |

Manufacturers of Welding Robots

A number of producers are well known for creating superior welding robot:

FANUC

Due to its wide range of products and significant market share in the automotive and electronics sectors, FANUC has about 17% of the global welding robot market.

The ABB

Leading the way in automation-driven industrial applications and robotic welding solutions with AI integration, ABB holds about 15% of the market.

KUKA

The KR CYBERTECH nano series robots from KUKA operate in shipbuilding facilities through their ability to access confined areas. The 1.5-meter reach of these robots allows them to weld fuel tank compartments that human operators cannot access.

Best Robots for Industrial Welding

Leading manufacturers have developed their highest performing welding robots, which include:

FANUC M-950iA/500

The FANUC M-950iA/500 operates as a heavy-duty industrial robot that executes automated welding tasks. The robot system reduces manufacturing delays at facilities while making their operations more efficient.

ABB IRB 6700

The ABB IRB 6700 functions as a multi-purpose robot that delivers both long reach capabilities and strong payload handling for executing multiple welding applications. The robot system provides manufacturers with increased production flexibility while simultaneously increasing their output levels.

KUKA KR 6 Arc

The KUKA KR 6 Arc robot system provides 6 kg payload capacity and 1,611 mm reach for arc welding operations. The robot system provides excellent performance for demanding arc welding operations because it allows both floor and ceiling mounting options for simple installation.

Frequently Asked Questions

- What Level Of Precision Do Robotic Welding Systems Achieve?

Robotic welding systems provide precise results because they maintain a repeatability level of ±0.1 mm, which results in uniform weld quality.

- What Advantages Does Robot Welding Technology Provide For My Welding Operations

Robotic welding systems deliver improved operational efficiency and enhanced safety measures, and precise results, which result in better production output and lower operational expenses.

- What Does A Welding Robot System Cost To Purchase?

The price range for welding robot extends from $25,000 to more than $250,000, depending on their specific features and operational capabilities.

- Will Robot Replace Human Workers In Welding Operations?

Robot now perform welding operations, but humans need to monitor complex tasks and inspect weld quality.

- What Is The Maximum Welding Speed That Robotic Welders Can Achieve?

Robotic welders operate continuously to achieve welding speeds that surpass manual welding methods.

Conclusion

Welding robots have revolutionized manufacturing through their ability to deliver precise results and safe operations at high speeds. Businesses seeking production improvements need to understand welding robot types and applications and select from the top manufacturers.