One of the most important tools in industrial automation is the robotic manipulator, which is used for safe, precise, and efficient operations in the manufacturing, healthcare, and space sectors. Here, we are going to explore what a robotic manipulator is and its variations, capabilities, applications, and more.

What is a Robotic manipulator?

A robotic manipulator, a mechanical tool, is created to carry out tasks that are generally challenging, hazardous for humans. It looks like the arm of the human being and is mostly made up of several segments (linkages) and joints that permit the existence of a variety of movements. These manipulators have end-equipped effectors- tools or grippers, which are used in a manipulative effect on objects to accomplish certain functions. They are widely used in different industries such as manufacturing, healthcare, and space exploration, to improve productivity, accuracy, and safety.

Types

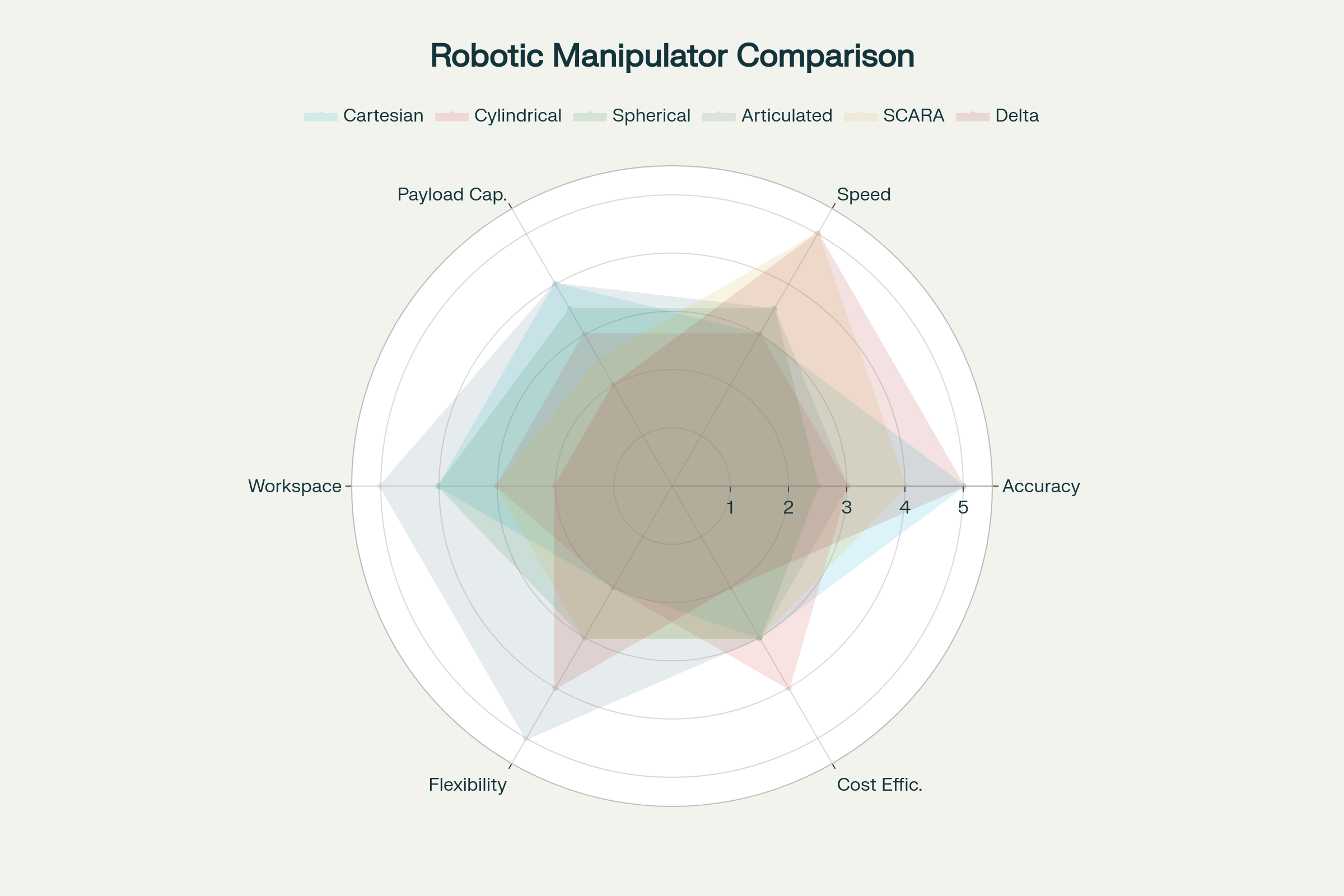

There are a number of different configurations of the robotic manipulators, each one applicable to a particular task and environment. These types of understanding can be used to choose the appropriate manipulator to use in a particular application.

Cartesian (Gantry) Manipulators/CRM

Gantry robots or also called cartesian manipulators, move within three linear directions, namely, X, Y, and Z–to make a rectangular work station. This design is highly precise and is suited to the tasks that involve high levels of precision, lateral, and direct movements.

Key Characteristics:

- Linear, X, Y, and Z-axis motion.

- High structural rigidity.

- Easy programming because of straight-line routes.

Used For:

- Pick-and-place operations.

- Material handling.

- Removing and loading machine tools.

Cylindrical Manipulators

Cylindrical manipulators allow linear movements in the Z-direction as well as rotation in the Z-direction axis, which forms a cylindrical workspace. This arrangement is appropriate for the tasks that involve a combination of horizontal and circular movements.

Key Characteristics:

- Linear movement in the Z direction.

- Will this motion of rotation about the Z-axis?

- Middle to light structural rigidity.

Used For:

- Assembly operations.

- Material handling.

- Coating applications.

Spherical (Polar) Manipulators

Spherical (Polar) Manipulators Spherical (Polar) Manipulators are manipulators that operate within a sphere of radius R on which the manipulator superimposes a positioning region of radius s called the target area. Spherical manipulators provide rotational movement around an immobile base to provide a workspace of spherical shape. This design offers extensive motion and is therefore suitable for any activity where extensive movement is required, flexibility.

Key Characteristics:

- Revolutions carried around a Churchill anchored base.

- Wide range of motion.

- Intermediate rigidity of the structure.

Used For:

- Welding

- Painting

- Material handling

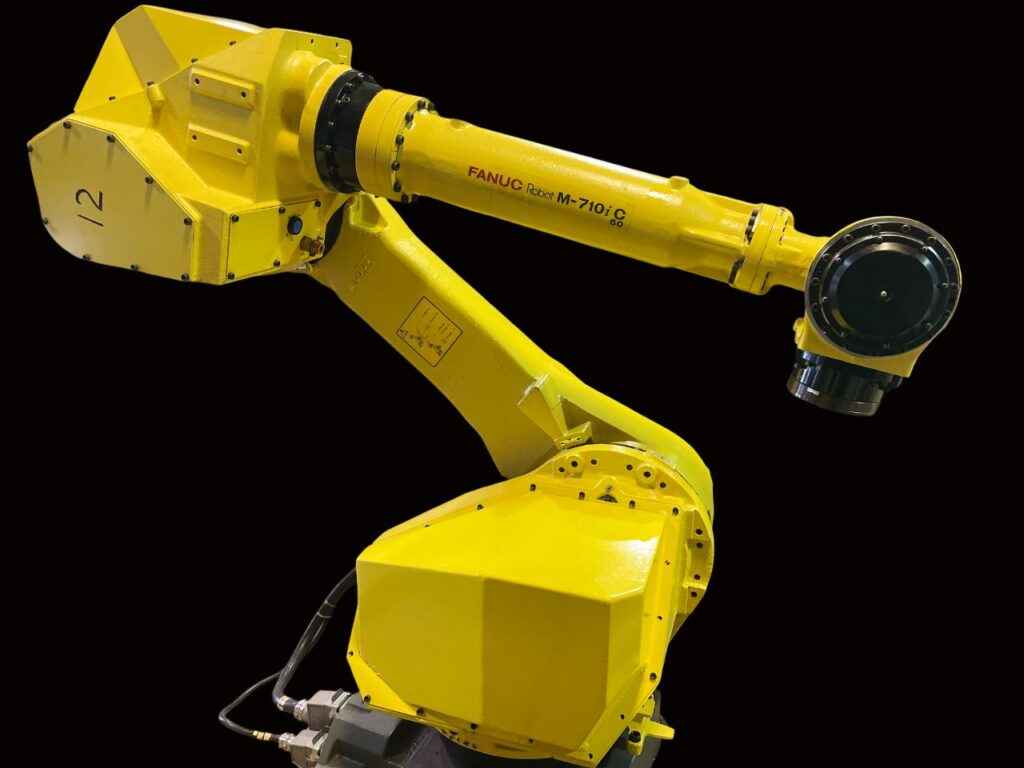

The Articulated (Anthropomorphic) Manipulators

Anthropomorphic robots are often called articulated manipulators that resemble the structure of the human arm in their design, as it has several rotary joints. It is a highly flexible design, which has a big motion radius, and is prepared them in accordance with demanding tasks.

Key Characteristics:

- Multiple rotary joints

- Much flexibility and mobility

- Complex control systems

Used For:

- Welding

- Material handling

- Assembly operations

Selective Compliance Assembly Robot Arm (SCARA)

SCARA robots are optimally configured to undertake high-speed, high-precision duties, especially on the horizontal plane. They include two parallel rotary joints of horizontal movements and a prismatic joint of vertical, kinematics, and partial obedience.

Key Characteristics:

- Two symmetrical rotary joints of horizontal movement.

- Vertical range of movement, one prismatic joint.

- Horizontal planar selective compliance.

Used For:

- Assembly operations

- Pick-and-place tasks

- Packaging

Delta (Parallel) Manipulators

Delta manipulators have three parallel arms with their identical base workspace. The configuration is suitable for tasks because it enables the high-speed and accurate movements needed for quick and precise positioning.

Key Characteristics:

- A common base has three parallel arms attached to it.

- High-speed movements.

- High precision.

Used For:

- Pick-and-place operations

- Packaging

- Sorting tasks

The Work of a Robotic Manipulator

A robotic manipulator works on a system of synchronized movements, which is regulated by a combination of both a mechanical design and a program. The procedure usually consists of several steps:

Design and Configuration: The design of the manipulator is designed to suit the tasks it is to do, with factors such as range of motion, payload carrying capacity, and precision requirements.

Actuation: The joints and the links are moved because of motors and actuators that allow movement towards the desired direction. This is because the nature and the positioning of the actuators would determine the desired performance.

Control Systems: Advanced control algorithms take as input signals, and modify the actuators’ movements to attain accurate positioning and orientation.

Programming: The manipulator is set to particular instructions, usually with complex algorithms, to work independently or in reaction to human orders.

Feedback Mechanisms: Sensors give real-time feedback of the position of the manipulator and its surroundings so that the manipulator can be adjusted and precision and safety assured.

End-Effector Interaction: The contact of the end-effector is with the objects and tasks that are executed, including: Depending on the programmed instructions, the welding, assembly, or material handling would be performed.

The Decision on the Right Manipulator

It is possible to choose the right robotic manipulator by taking into account several factors:

Task Requirements: Determine which – precision, speed, or payload capacity – of the application is of primary importance.

Production Volume: Decision to make on whether the application is high volume or repetitive, or flexible manufacturing capacity.

Budget Constraints: Compare the initial investment to the long-term expected payoff of the investment.

Programming Requirements: Take into consideration that the nature of the programming and advanced control systems is required.

Environmental Conditions: This is a factor that takes into consideration such factors as clean room standards, exposure to harsh environments, or hazardous materials.

Frequently Asked Questions:

1. What is the distinction between an instance of a robot and a robotic manipulator?

One of the elements of a robot is the robotic manipulator, which is physically designed to offer its services to objects. The system of sensors, control systems, and manipulators does not create a robot but forms part of it.

2. What is the most popular form of robot manipulator?

One of the most widespread ones is articulated manipulators, as they are flexible and have a wide range of movement, and thus can be used in different applications.

3. What is the price of a robotic manipulator?

The price depends widely on such factors as complexity, payload capacity, and application. The price may vary between thousands and even hundreds of thousands of dollars.

4. Maintenance of robotic manipulators: What do they need?

Routine maintenance also involves repairing and external replacement of the worn-out parts, calibration of the sensors, updating software, and making sure that every part is working properly.

5. Is it possible to have robotic manipulators alongside humans, safely?

Yes, robotic manipulators can operate in the presence of humans safely by considering safety procedures, sensors, and collaborative designs.

Conclusion

Robotic manipulators are an important part of the modern automation ecosystem due to their consistency, efficiency, and safety in a variety of sectors. Knowing the types, functions, and selection standards will help to increase appropriate robotic manipulator use.