Painting robots have become a revolution in the constantly changing environment of manufacturing and automation. In this paper, the authors will explore the different categories of painting robots, their advantages, and the main brands in the market. We shall also discuss the cost and the turnover on investment (ROI) of these advanced machines to give a thorough analysis of the cost to any company that may want to consider automation in its painting process.

What Are Painting Robots?

The painting robots are automated machines that apply paint or coating on different surfaces with accuracy and efficiency. These robots apply high technology in order to bring order and minimize human error. The industry reports show that the market for painting robots globally is going to grow considerably, as more industries are seeking automation. Robotic painters may be used in many settings, such as the assembly line of cars or in furniture manufacturing, becoming more productive and minimizing labor expenses. These robots can operate around the clock without exhaustion, and hence, they are transforming the way people paint in various industries.

Types

There are several types of painting robots, each of which is aimed at particular applications and methods. The most prevalent types of painting robots are examined below, and their characteristics are discussed.

1. Spray Painting Robots (Most Common)

The most common one in the industry is the spray painting robots. They are made to spray paint with the help of a spray nozzle to get a coating of paint that is well distributed on surfaces.

Benefits:

- Fast application decreases the cycle times.

- Good finish with minimal overspray.

- Capacity to deal with complicated shapes and surfaces.

Used for:

- Automotive painting.

- Furniture finishing.

- Coating of industrial equipment.

Painting Process

- Cleaning and preparation of surfaces.

- Pattern programming of robots.

- Application of paint with spray nozzles.

- Curing or drying of the paint.

2. Electrostatic Painting Robots

The painting robots are electrostatic robots that utilize an electrostatic charge to make the paint particles stick to the surface, which makes the application more efficient.

Benefits:

- Decreased wastage of paint, considering high transfer efficiency.

- Better coverage of complicated geometries.

- Cleaner with reduced VOC.

Used for:

- Metal parts coating.

- Appliance finishing.

- Automotive components

Painting Process

- Cleaning and preparation of surfaces.

- Use of the electrostatic charge.

- Application and atomization of paint.

- Drying of the paint.

3. Autonomous/ Self-Driving Painting Robots (AI-Powered)

In autonomous painting robots, artificial intelligence is used to adjust the painting methods depending on the real-time feedback regarding the environment.

Benefits:

- Increased flexibility to different surfaces and environments.

- Less human intervention is required.

- The capability to learn continuously to become more efficient.

Used for:

- Custom applications in painting.

- Complicated industrial conditions.

- lines with high variation of production.

Painting Process

- Primary surface evaluation with sensors.

- The Environmental data Dynamic programming.

- Real-time adjustments in the application of paint.

- Last inspection and quality check.

4. Automatic Painting Robot

Automatic painting robots are aimed at large volume production, which generates a level of production with reproducible results.

Benefits:

- Large throughput and low downtime.

- Stabilized quality in huge batches.

- Lower workforce expenses and improved security.

Used for:

- Automotive parts mass production.

- Furniture production on a large scale.

- Coating of industrial machinery.

Painting Process

- Pre-treatment of surfaces.

- Computer-controlled paint deposit.

- Checks at the process level.

- Final curing and inspection.

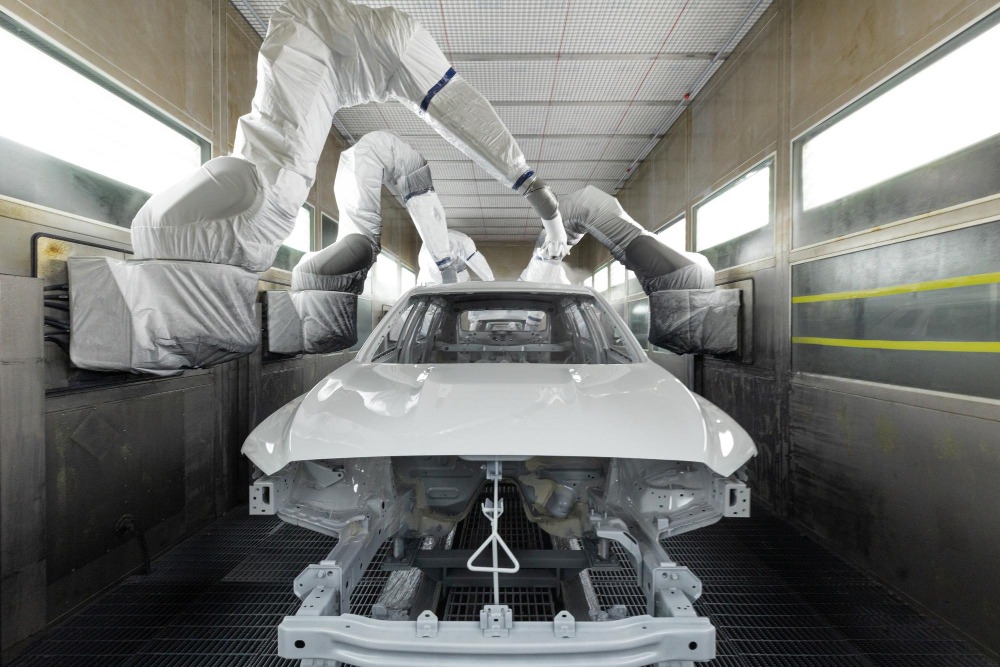

5. Robotic Paint Booths

The robotic paint booths incorporate the use of robots in the painting process, where robots are installed in a controlled setting to achieve optimisation of the painting process.

Benefits:

- Regulated circumstances in the best painting.

- Minimized contamination and defects.

- increased operator safety.

Used for:

- Automotive assembly lines.

- Finishing of aerospace components.

- Manufacturing of high-end furniture.

Painting Process

- Preparation and cleaning of surfaces.

- Specific task robot programming.

- Application of paint in the booth.

- Curing and quality control.

Cost and ROI Analysis

Businesses can make a lot of returns on investing in painting robots. Although early investment in the buying and installation of these robots may be quite high, the long-term payoff usually becomes greater than the costs. The companies are likely to get a cut in labor costs, higher production rates, and higher quality control. ROI can be obtained within 2 to 5 years, depending on the size of the business and the kind of robot deployed, as indicated by industry estimates. Also, the less paint and other waste, and the expense of rework further increase the economic viability of robotic painting solutions.

Leading Painting Robot Manufacturers/Producers

With the increasing market of painting robots, various manufacturers have already positioned themselves to be the best in the field. These are the companies that are praised as having innovative technologies and trustworthy goods.

1. FANUC

FANUC is a world leader in robotics and automation, providing various painting robots with high levels of precision and efficiency. The automotive and industrial applications of their robots are also very popular, and they offer high-speed solutions to the painting industry with little overspray. The sophisticated nature of programming at FANUC can easily integrate with the available production lines.

2. ABB

ABB has a reputation for the latest robotics technology, with one of its most striking being the painting robots that offer the highest performance. Their robots are flexible and can handle different painting activities, which is why they can be applicable in different industries. At ABB, sustainability can be seen through the fact that their painting solutions are environmentally friendly.

3. Kawasaki

The robots created by Kawasaki are characterised by high precision and speed, and they can be used in mass production. Kawasaki is highly focused on innovation, and this has seen it come up with high-end robotic solutions that contribute to productivity and the minimization of operational expenses in the painting process.

4. KUKA

KUKA is a strong competitor in the robotics industry and provides a variety of painting robots that are successful in complicated tasks. They have the most advanced sensors and AI in their robots that enable real-time changes in the painting process. KUKA is also dedicated to quality, and thus will perform well in harsh conditions.

5. Motoman

Motoman is a branch of Yaskawa that deals with robotic systems in many industries, such as painting. Their robots that do painting are very efficient and precise, which offer uniform results in dissimilar applications. The ease of using its programming system is what makes Motoman easy to implement robotic painting solutions for businesses.

6. Universal Robot

Universal robots in painting are revolutionizing the way industries execute their painting processes. These robotic systems are proving to be more flexible, precise, and cost-effective, making them invaluable for manufacturers who want to enhance efficiency while maintaining high-quality standards. As technology develops, the functionalities of universal robots will likely continue to improve, making them only more significant in the painting industry. Some key factors of Universal robots for painting are Flexibility, Ease of use for end-users, Very precise output, Safety (AI-powered collision guard), and the most effective is the cost of these units compared to their competitors.

Manual Painting vs. Robotic Painting

Manual painting is more cost-effective than robotic painting, because it utilizes a brush and paint application and less robot involvement.<|human|>Manual painting vs. robot painting. Manual painting is cheaper than robotic painting, as it uses a brush and paint application and reduces robot participation.

Efficiency, quality, and cost are some of the factors that usually determine whether to use manual or robotic painting. Robotic painting is accurate and repeatable, whereas manual painting is not. Robots can work 24/7, hence minimizing the cycle time and enhancing throughput. Also, robotic painting helps to save amounts of paint and makes the process safer, as it reduces the contact of humans with dangerous substances. Robotic painting is increasingly being adopted by most manufacturers as industries keep adopting automation.

Frequently Asked Questions

- What are industrial paint robots?

Industrial paint robots are automated machines designed to apply paint or coatings to various surfaces in manufacturing settings. They utilize advanced technology to ensure precision, consistency, and efficiency in the painting process.

- What are the uses of paint robots?

Automation of the painting process is achieved through the use of paint robots in many industries, such as automotive, furniture, and industrial equipment manufacturing.

- How does a paint robot work?

A paint robot is a programmed paint robot that applies paint evenly and correctly on surfaces with the help of advanced sensors and technology.

- What is the cost of industrial paint robots?

The cost of industrial paint robots can vary widely based on parameters such as the type of robot, its capabilities, and the complexity of the application. Depending on specifications and features, prices can range from tens of thousands to a few hundred thousand dollars.

- What is the return on investment (ROI) for industrial paint robots?

The ROI of industrial paint robots can be significant, with payback in around 2 to 5 years. Factors that drive ROI include lower labor costs, increased production rates, reduced paint waste, and improved product quality.

- What makes a painting robot safe?

Robots that are used to paint have safety features like emergency stop buttons, protective enclosures, and advanced sensors to prevent accidents and ensure safe use.

Conclusion

To recap, robots that paint are changing the nature of manufacturing by providing effective and quality painting options. There are different kinds of robots, such as spray painting, electrostatic, and autonomous robots, so businesses will be able to find the most suitable one. Robotic painting is highly beneficial in the sense that it eliminates labor expenses, enhances quality, and increases the speed of production, and hence is worth investing in. The future of painting robots is bright, as the major manufacturers keep innovating, and new developments will bring greater automation in different industries.