Applying an industrial robot requires many variables to be considered. The most common things to look at in a robot are:

- Robot condition

- Load capacity

- And most important, cost

Here is Why You Should Purchase a Used Robot

These factors determine which robot a company should buy. The biggest factor is cost — often the deciding point in whether robotic automation fits within a manufacturer’s budget.

Fortunately, industrial robots have long service lives, making used robots a budget-friendly alternative.

The used robot market has grown significantly as manufacturers shift from labor-heavy processes to automation.

Affordable

Used robots are significantly cheaper than brand-new ones — often up to 50% less.

This makes robotic automation accessible for small and medium-sized manufacturers.

Even large companies benefit from the savings.

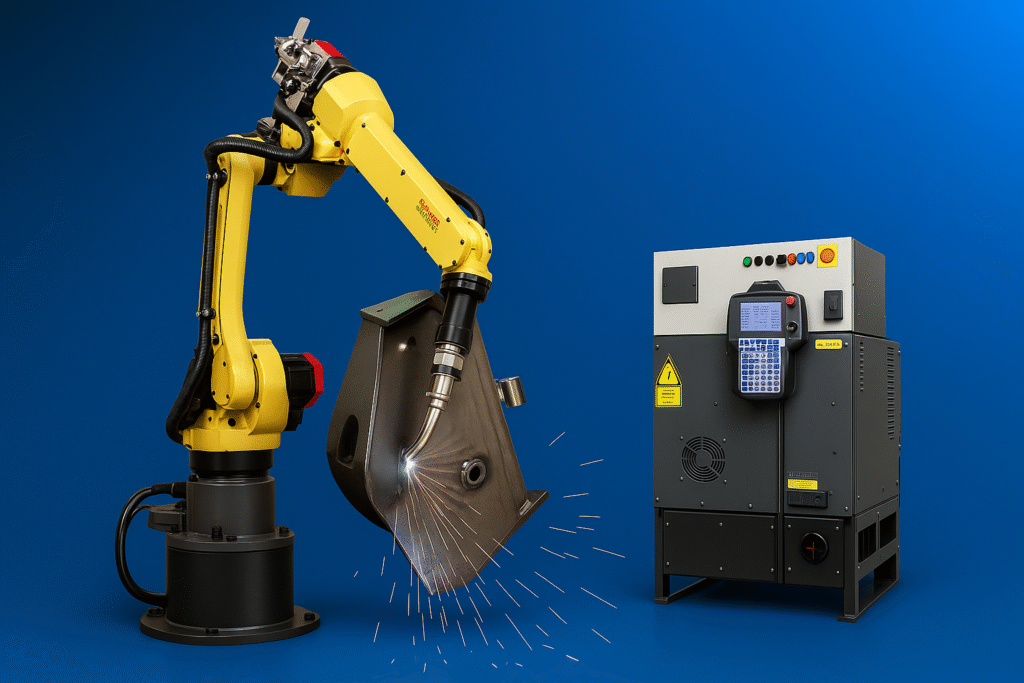

For example, using a FANUC robot such as the

LR Mate 200iC

still delivers excellent efficiency at a fraction of the cost.

With lower upfront investment, companies achieve a faster return on investment.

Compatibility with Pre-existing Equipment

Buying a used articulated robot also makes sense when replacing an older 6-axis robot.

Used robots can match older controllers, pendants, power supplies, and end-of-arm tooling.

This compatibility reduces additional upgrade costs and allows manufacturers to keep their existing robotic infrastructure.

Trustworthy Automation Solution

Used robots remain highly reliable automation tools.

Just because a robot is used does not mean it is less effective.

Most used robots have already been proven in actual production environments.

For example, if you buy a used Motoman MA1400 welding system, you can be confident that it will function properly because it has already been deployed in welding automation.

Used robots can improve product quality, reduce cycle times, boost efficiency, and lower operating costs.

Familiarity for Techs

Purchasing a used robot also gives your technicians and operators familiarity with proven models.

Since these robots have been around for years, many techs already know how to program, integrate, and maintain them.

This means faster setup, easier troubleshooting, and reduced downtime.

Technicians also understand preventive maintenance needs, helping keep the robot operating at peak performance.

Have a used robot for sale? Give us a call today!